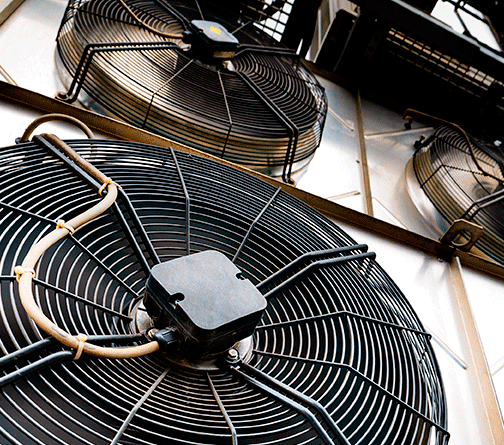

Cold storage rooms (0º positive)

Self-supporting metal sandwich panels insulated with polyurethane with tongue and groove joint, designed for the construction of large refrigerated or air-conditioned warehouses and cold rooms.

Refrigerated sandwich panels

Panel finished in phenolic wood / galvanized. Used as flooring in cold rooms.

| CHARACTERISTIC | VALUE OBTAINED DC PANEL | VALUE REQUIRED BY STANDARD UNE 41-950 |

| Compressive strength (10% deformation) | 0.185 N/mm2 = 1.89 kg/cm2 | ≥ 0.10 N/mm2 |

| Modulus of elasticity in compression | 5.24 N/mm2 | ≥ 3 N/mm2 |

| Shear strength | 0.187 N/mm2 | ≥ 0.10 N/mm2 |

| Constant stress modulus | 3.14 N/mm2 | ≥ 2 N/mm2 |

| Tensile strength perpendicular to the covering layers | 0.132 N/mm2 | ≥ 0.10 N/mm2 |

| Tensile modulus of elasticity | 4.37 N/mm2 | ≥ 3 N/mm2 |

| Foam density | 40.6 kg/m3 | ≥ 38 kg/m3 |

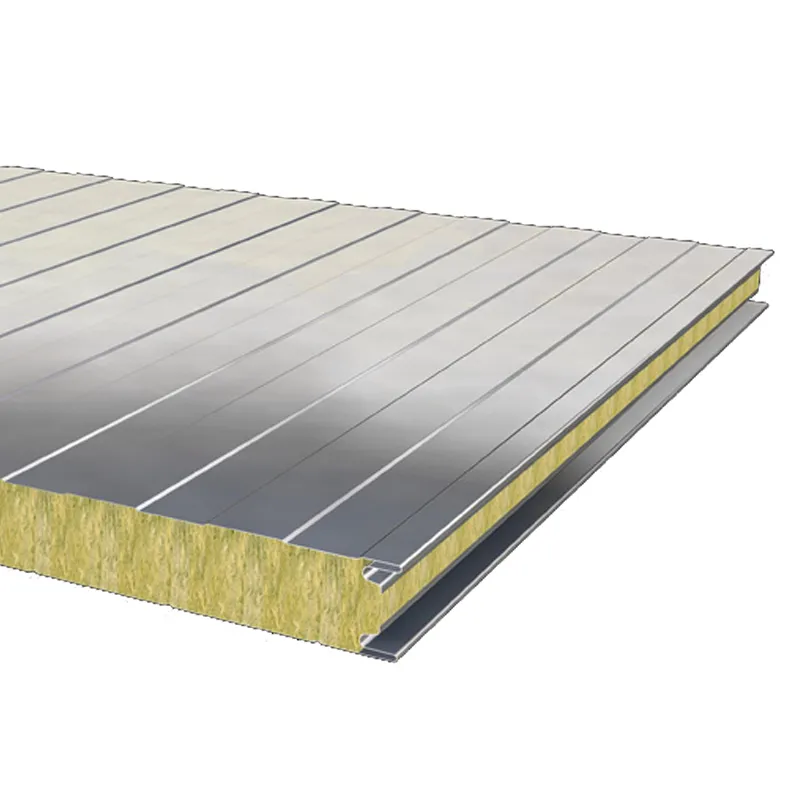

Self-supporting metal sandwich panels insulated with polyurethane with tongue and groove joint, designed for the construction of large refrigerated or air-conditioned warehouses and cold rooms.

The self-supporting panels with eccentric hook fastening system consist of a steel sheet on each face and a core of rigid polyurethane or polyisocyanurate foam (B-s2-d0 / B-s1-d0). These panels have been specially designed for the construction of facades of industrial and commercial buildings and partitions in general.

The self-supporting metal sandwich panel with rock wool core is designed for fireproof sectorization in industrial, commercial and residential buildings. Its composition guarantees high fire resistance, in addition to excellent thermal and acoustic insulation properties, complying with the most demanding safety standards.